Dear sir / madam,

As you probably read already in our last newsletter in 2023, GTA has invested a lot in the machinery during the last years. With these newsletters together with our social media we want to show you a little more about these machines. Perhaps these machines and her possibilities can mean something for you also. As told we can even better produce bigger series 24/7, this can be gears as well as other fine mechanical products. Besides this production of bigger series we remain producing the smaller series in the daytime.

Click on Machinery 2024 for more information about our machines and possibilities.

Multi-tasking machine Integrex i-200:

We started using a Mazak Integrex i-200 multi-tasking machine besides the Mazak Integrex i-100 in 2020. With this i-200 multi-tasking machine we can machine compact and complex workpieces in 1 machine, this gives us many advantages. The machine can do turning and milling operation until a maximum diameter of 500mm. The maximum length which can be machined is 854mm.

This machine is equipped with an automatic feeder of the bar material. Besides the automatic feeder this Integrex i-200 is equipped with a robot frontloader for loading and unloading the workpieces. The frontloader is equipped with 5 product drawers. This is important for our 24/7 production and for remaining competitive also for bigger series.

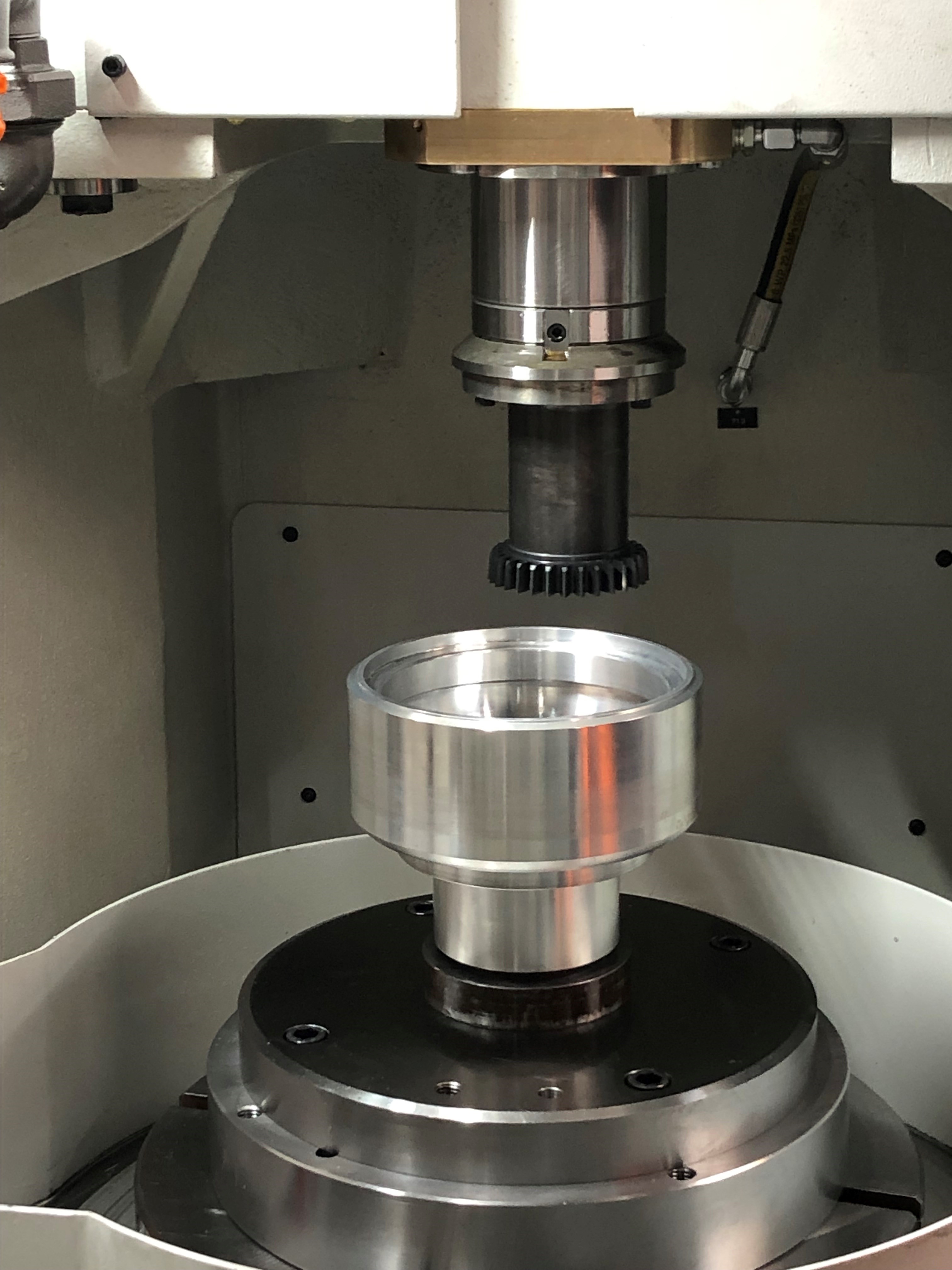

CNC Gear-shaping machine AM250:

We've installed in our plant, located in Someren, a new CNC Gear-shaping machine in 2022. This machine will be used for shaping of typical cylindrical spur and helical, external and internal gears. The maximum workpiece diameter is 300mm and we can produce up to Modul 8. The stroke length has a maximum of 110mm.

Quick turn QTE-200SG with barfeeder:

We installed a Mazak Quick Turn QTE-200SG CNC turning center in 2021. The maximum workpiece diameter for this turning center is 290mm. Also this machine we've equipped with an automatic feed for the bar material. This is important for our 24/7 production and for remaining competitive also for bigger series.

You can see we have taken and will continue to take steps to continue to serve you, our customer, well in the future. In the next newsletter we will show you what other investments we have made.

If you have any questions, send an e-mail to sales@gta.nl or contact us by phone.

If you do not wish to receive this newsletter anymore, please unsubscribe via the link below.

Nijverheidstraat 4, 5711 CZ Someren

Nederland

T: +31 (0)493 242200

E: info@gta.nl

www.gta.nl